Conveyor belts

Roller conveyors

Belt conveyors

Hinge conveyor

Roller conveyors

This type of conveyor belt comprises a series of rollers along its path, which can have different shapes, diameters and materials depending on the load to be transported. The roller conveyor belts may incorporate spaced motorized rollers at different time or space intervals to drive or brake the load (s) in the production circuit.

Since the geometry of said rollers obviously favors the sliding of the loads, it is frequent that variations of the slope of the circuits are used, which causes the sliding of the load under the effect of gravity by using the minimum of energy possible for the transfer of goods. Widely used in logistics, roller conveyor belts are a formidable and effective solution for a multitude of internal transfer projects.

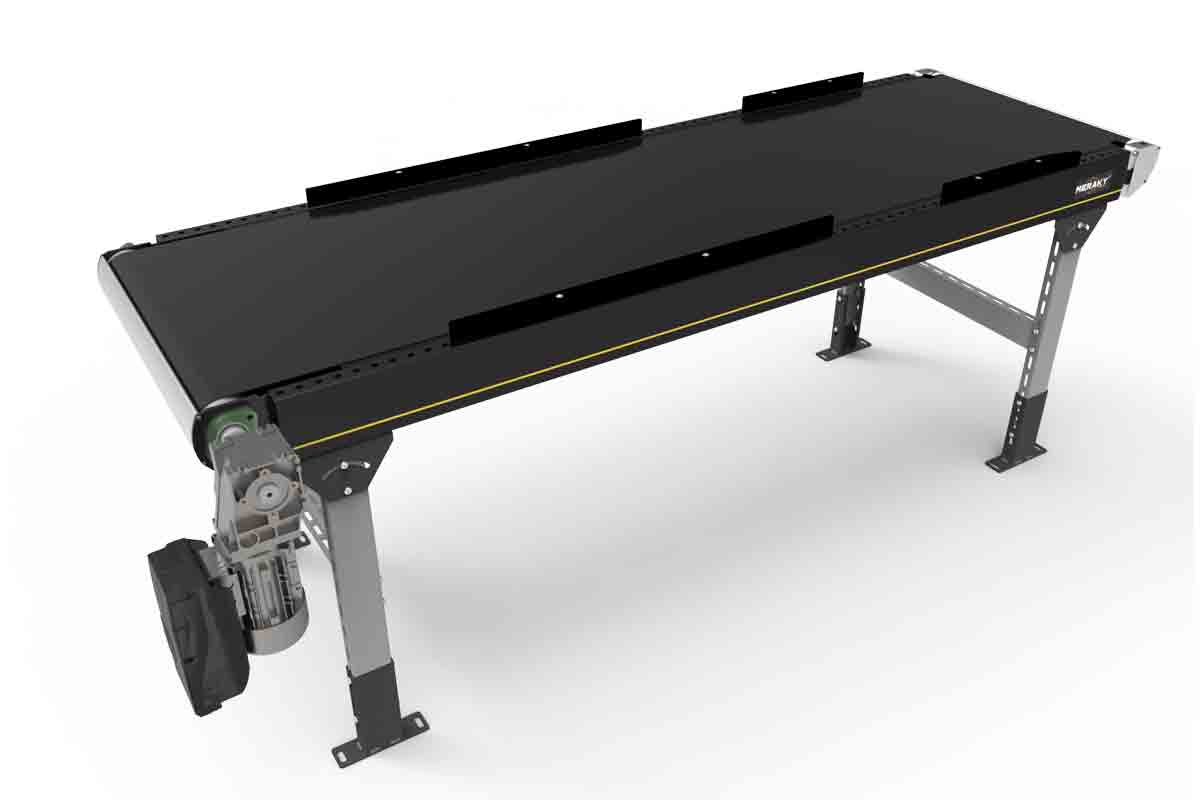

Belt conveyors

The type of belt conveyor is frequently used in transporting or transporting smaller and larger quantities of material. The beverage or cement industries, for example, use belt conveyors to transfer their different raw materials from a multi-compartment central stock, or other goods transport elements such as dump trucks, tractors, concrete mixers …

Despite this, the use of conveyor belts is not exclusive to any of these production sectors. The truth is that the versatility offered by conveyor belts is such that it is difficult to evaluate all applications where they can improve productivity and performance. If you have a project where the estimated manufacturing process can and should be automated, contact us to implement the best industrial automation solution to meet your needs.

Hinge conveyor

Hinged conveyor belts are a feeding system that adds, to what was originally designed as a belt conveyor, hinges in three-dimensional format that facilitate transitions between points with complex trajectories.

Frequently used in the food industry, for the transport of food and drink, the fields of application of conveyor belts are generally industrial projects or parts of a line of work in which the loads are not usually excessively bulky and heavy, but they require great speed and flexibility in the path between points.

Industrial customized solutions in Meraky

Our projects go through the design of the best solution, and this design goes through the exhaustive knowledge of the manufacturing process that takes place in the facility. Our team of specialized engineers will determine which components are the most appropriate taking into account factors such as the load in question, the overall durability of the entire structure, the necessary speed of the production line and even the need for may or more automation, determined by the availability of operators at certain times and at certain stages of the overall process. Ask for a quote without commitment. At Meraky, it’s a pleasure to help you.